St Louis powder coating has become one of the most sought-after surface finishing solutions for both industrial and consumer applications. This cutting-edge technology offers unmatched durability, versatility, and aesthetic appeal, making it an ideal choice for a wide range of materials, including metals, plastics, and even wood. Whether you're looking to enhance the appearance of your automotive parts, protect your outdoor equipment, or add a vibrant finish to your home decor, powder coating is the answer.

In today's competitive market, businesses and individuals are constantly searching for ways to improve the quality and longevity of their products. St Louis powder coating stands out as a superior option because it provides a more eco-friendly and cost-effective alternative to traditional liquid painting methods. The process involves applying a dry powder onto a surface, which is then cured under heat to create a robust and long-lasting finish.

As we delve deeper into this article, you'll discover why St Louis powder coating is becoming increasingly popular across various industries. From automotive and construction to home improvement and art, this versatile technique offers numerous benefits that cater to diverse needs. So, let's explore what makes powder coating an excellent choice for your next project and how it can transform your surfaces into works of art.

Read also:Giannis Antetokounmpos Net Worth 2025 Salary Contracts And Nba Earnings

Table of Contents

- Introduction to St Louis Powder Coating

- Key Benefits of Powder Coating

- The Powder Coating Process

- Applications of St Louis Powder Coating

- Comparison with Other Coating Methods

- Environmental Impact

- Cost Considerations

- Durability and Maintenance

- Tips for Choosing the Right Service

- The Future of Powder Coating

Introduction to St Louis Powder Coating

Understanding Powder Coating

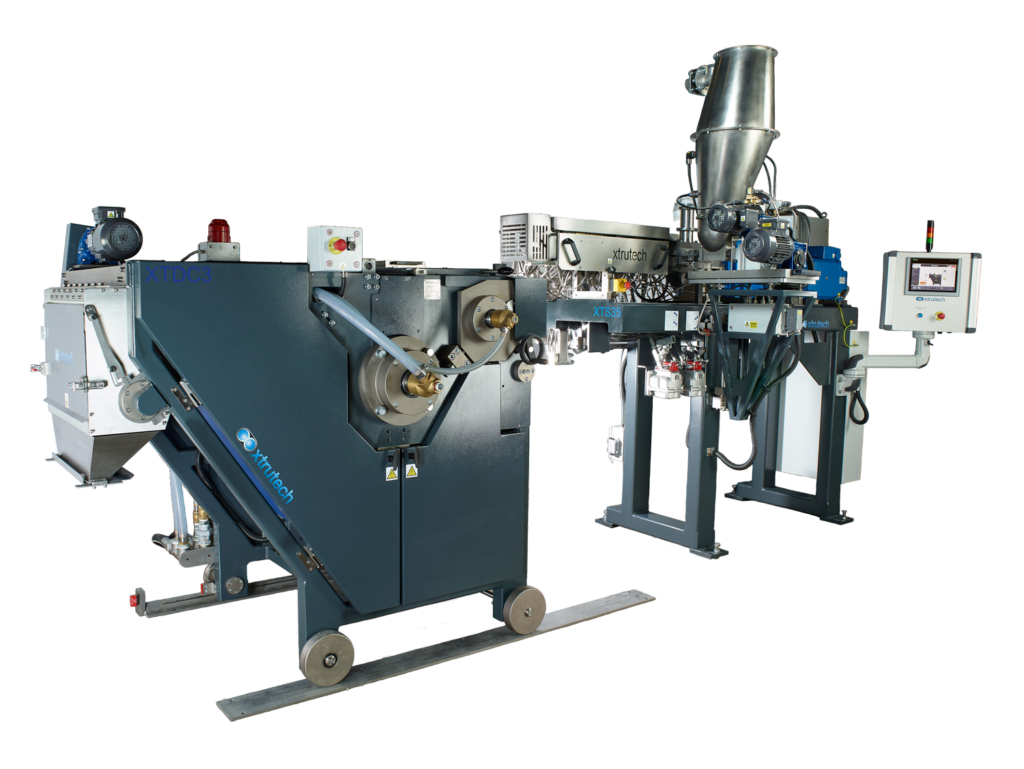

St Louis powder coating is a modern finishing technique that has gained significant traction in recent years due to its exceptional performance and versatility. Unlike traditional liquid paints, powder coating uses finely ground particles of pigment and resin that are electrostatically charged and applied to a surface. Once applied, the coated item is heated in an oven, causing the powder to melt and form a durable, seamless coating.

This method not only enhances the appearance of the object but also provides excellent protection against environmental factors such as UV rays, moisture, and abrasion. As a result, powder coating is widely used in industries where durability and aesthetics are paramount.

Why Choose St Louis?

St Louis has emerged as a hub for high-quality powder coating services, thanks to its experienced professionals and state-of-the-art facilities. Businesses in the region have embraced this technology to meet the growing demand for durable and visually appealing products. Whether you're a local business owner or an individual looking to upgrade your belongings, St Louis offers a wide range of options to suit your needs.

Key Benefits of Powder Coating

St Louis powder coating offers numerous advantages over traditional coating methods. Below are some of the key benefits:

- Durability: Powder coatings are highly resistant to chipping, scratching, and fading, making them ideal for both indoor and outdoor applications.

- Versatility: This technique can be used on a variety of materials, including metals, plastics, and wood, allowing for endless possibilities in design and functionality.

- Eco-Friendly: Unlike liquid paints, powder coating does not release harmful volatile organic compounds (VOCs) into the atmosphere, making it a more environmentally friendly option.

- Cost-Effective: While the initial cost may be slightly higher, the long-term savings in maintenance and longevity make powder coating a wise investment.

- Customization: With a wide range of colors, textures, and finishes available, powder coating allows you to achieve the exact look you desire.

The Powder Coating Process

The process of St Louis powder coating involves several steps to ensure a high-quality finish. Here's a breakdown of the procedure:

Preparation

Before applying the powder, the surface must be thoroughly cleaned and prepared to ensure proper adhesion. This step may involve sandblasting, chemical cleaning, or other methods to remove dirt, grease, and rust.

Read also:Cj Strouds Net Worth In 2025 A Closer Look At His Financial Journey

Application

The powder is applied using a specialized spray gun that charges the particles, allowing them to adhere to the grounded surface. This electrostatic attraction ensures even coverage and minimal waste.

Curing

Once the powder is applied, the object is placed in an oven and heated to a specific temperature. The heat causes the powder to melt and flow, forming a uniform coating that hardens as it cools.

Applications of St Louis Powder Coating

St Louis powder coating is used in a variety of industries and applications, including:

- Automotive: Coating automotive parts such as wheels, bumpers, and engine components for enhanced durability and aesthetics.

- Construction: Protecting metal structures, fences, and railings from corrosion and environmental damage.

- Home Improvement: Adding vibrant finishes to furniture, appliances, and decorative items for both indoor and outdoor use.

- Art and Design: Creating unique and visually striking pieces with custom colors and textures.

Comparison with Other Coating Methods

While St Louis powder coating offers many advantages, it's essential to compare it with other coating methods to determine the best choice for your project:

Traditional Liquid Painting

Liquid paints are often cheaper upfront but can be less durable and more prone to chipping and fading. They also release VOCs, making them less environmentally friendly than powder coating.

Electroplating

Electroplating provides a strong metallic finish but is limited in terms of color options and can be more expensive for certain applications. It also requires precise control over the plating process, which can add complexity to the project.

Environmental Impact

St Louis powder coating is widely regarded as an eco-friendly alternative to traditional coating methods. By eliminating the use of solvents and VOCs, this technique significantly reduces air pollution and environmental damage. Additionally, any excess powder can be collected and reused, minimizing waste and promoting sustainability.

Cost Considerations

While the initial cost of St Louis powder coating may be higher than some alternatives, the long-term benefits often outweigh the expense. The durability and low maintenance requirements of powder-coated surfaces result in significant savings over time. Moreover, the ability to customize colors and textures adds value to the product, making it a worthwhile investment.

Durability and Maintenance

One of the standout features of St Louis powder coating is its exceptional durability. Properly applied coatings can last for years with minimal maintenance, even in harsh environmental conditions. To ensure longevity, it's important to follow a few simple maintenance tips:

- Regularly clean the surface with mild soap and water to prevent the buildup of dirt and debris.

- Avoid using abrasive cleaners or tools that could scratch or damage the coating.

- Inspect the surface periodically for signs of wear or damage and address any issues promptly.

Tips for Choosing the Right Service

When selecting a St Louis powder coating service, consider the following factors:

- Experience: Look for a provider with a proven track record of delivering high-quality results.

- Equipment: Ensure the service uses modern equipment and technology to achieve the best possible finish.

- Customization Options: Choose a provider that offers a wide range of colors, textures, and finishes to meet your specific needs.

- Customer Reviews: Read reviews and testimonials from previous customers to gauge the reliability and quality of the service.

The Future of Powder Coating

As technology continues to evolve, St Louis powder coating is likely to become even more advanced and versatile. Innovations in powder formulations, application techniques, and curing processes will further enhance the performance and sustainability of this method. Additionally, the growing demand for eco-friendly solutions will drive the adoption of powder coating across various industries.

Conclusion

St Louis powder coating offers a superior finishing solution for a wide range of applications, combining durability, versatility, and eco-friendliness in one package. Whether you're looking to protect your assets, enhance their appearance, or increase their value, powder coating is an excellent choice. By choosing a reputable service provider and following proper maintenance practices, you can enjoy the benefits of this innovative technique for years to come.

We invite you to share your thoughts and experiences with St Louis powder coating in the comments below. If you found this article helpful, don't hesitate to share it with your friends and colleagues. For more informative content on coating technologies and other related topics, explore our website and stay updated on the latest trends and developments in the industry.

References:

- Industrial Finishing Magazine

- Coating Materials News

- Environmental Protection Agency (EPA)